Imagine being able to wear unique, one-of-a-kind jewelry that is custom-made just for you. With the advent of 3D printing technology, this dream can now become a reality. Custom 3D Printed Jewelry Design is an innovative and exciting way to create personalized accessories that reflect your individual style and taste. This article will explore the world of custom 3D printed jewelry design, discussing the process, benefits, and limitless possibilities it brings to the world of fashion. Get ready to embark on a journey of self-expression and creativity like never before.

Benefits of Custom 3D Printed Jewelry

Unique and Personalized Designs

Custom 3D printed jewelry offers the unique advantage of creating designs that are personalized and one-of-a-kind. With this technology, you have the freedom to express your individual style and create pieces that truly reflect your personality. Whether you want to commemorate a special occasion or simply make a fashion statement, custom 3D printed jewelry allows you to have a piece that is exclusively yours.

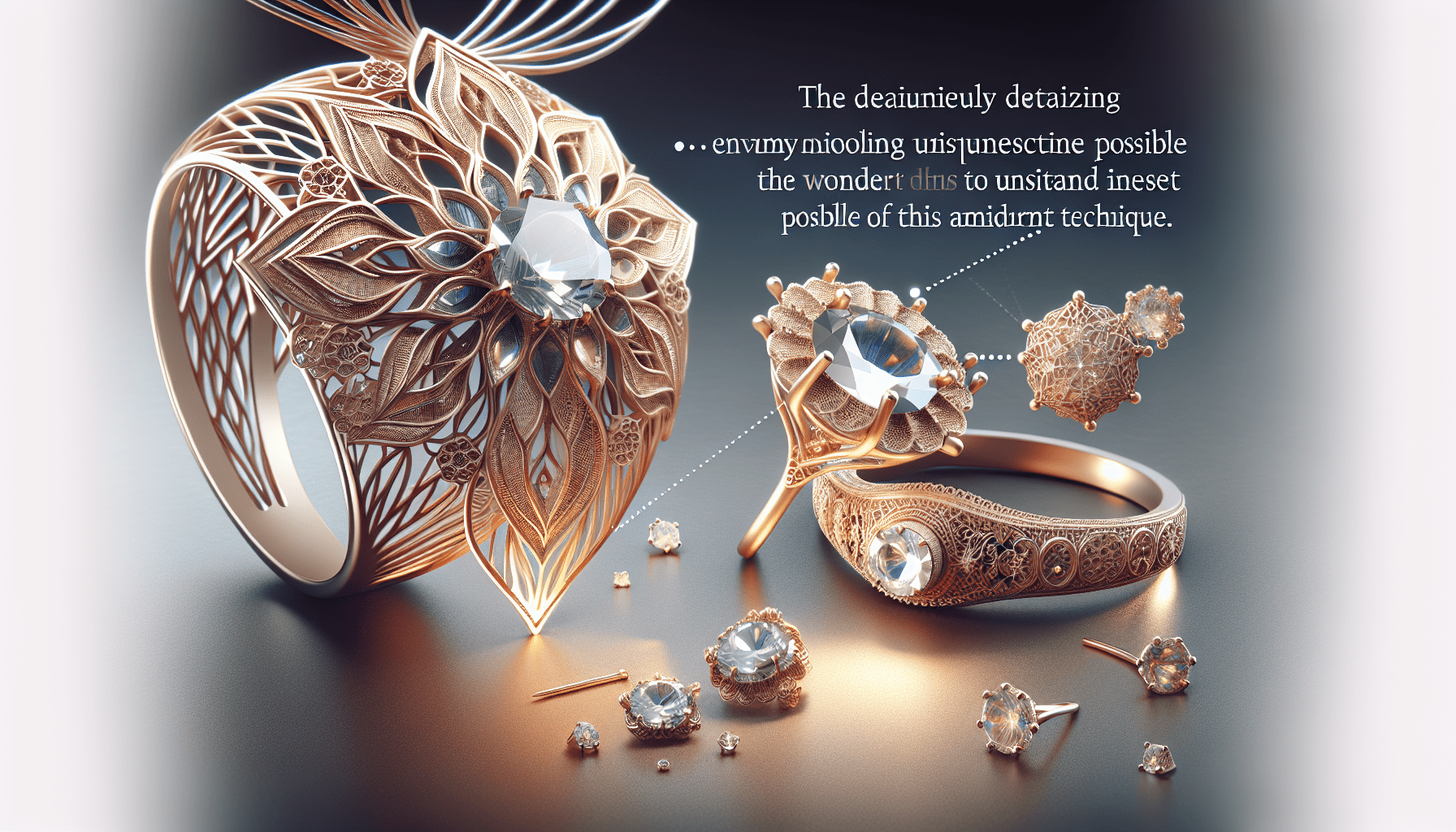

Precise and Intricate Detailing

One of the remarkable benefits of 3D printing is the ability to achieve intricate detailing with a high level of precision. Traditional jewelry-making methods often require skilled craftsmanship, which can limit the complexity and fine details of a design. However, with custom 3D printing, even the most intricate designs can be brought to life with incredible accuracy. The level of detail that can be achieved through 3D printing technology is truly impressive and allows for stunning jewelry pieces that catch the eye.

Cost-effective Production

Custom 3D printed jewelry offers a cost-effective production method compared to traditional manufacturing techniques. Traditional jewelry-making methods often involve labor-intensive processes and the use of expensive materials. These factors can significantly drive up the cost of production. In contrast, 3D printing eliminates many of the manual processes, reducing labor costs. Additionally, 3D printers can utilize a range of materials, including more affordable options, without compromising on quality. This makes custom 3D printed jewelry a more affordable option for those looking for unique and personalized pieces without breaking the bank.

Quick Turnaround Time

Custom 3D printed jewelry allows for a significantly quicker turnaround time compared to traditional jewelry-making methods. With traditional manufacturing, the process can be time-consuming and involve various steps such as mold-making and casting that can take weeks or even months. However, with 3D printing, the process is streamlined and can be completed in a fraction of the time. Once the design is finalized, the 3D printing process can begin, and the jewelry piece can be ready for finishing touches within a matter of hours or days. This quick turnaround time is especially advantageous for individuals who are looking for last-minute personalized gifts or need jewelry for special occasions.

Process of Custom 3D Printed Jewelry Design

Conceptualization and Designing

The process of custom 3D printed jewelry design starts with conceptualization and designing. This involves working closely with a jewelry designer or using specialized computer software to visualize your ideas. During this stage, you can explore various design options, experiment with different shapes and patterns, and make adjustments to create the perfect piece of jewelry that matches your vision.

3D Modeling and CAD Software

Once the design is finalized, the next step is to create a 3D model of the jewelry using computer-aided design (CAD) software. CAD software allows for precise measurements and detailing of the design. With CAD software, the jewelry designer can bring your design to life digitally, giving you a realistic representation of how the final piece will look.

Material Selection

After the 3D model is complete, the next step is to select the appropriate material for the jewelry piece. Custom 3D printed jewelry can be made using a variety of materials, including precious metals like gold and silver, as well as plastics, resins, and even ceramics. The material selection depends on factors such as the desired aesthetics, durability, and budget.

Printing and Finishing

Once the material is selected, the 3D printing process begins. The 3D model is sent to the 3D printer, which uses additive manufacturing techniques to build the jewelry layer by layer. Depending on the complexity and size of the design, the printing process can take several hours to complete. After the printing is finished, the jewelry piece undergoes various finishing processes, such as polishing and surface treatments, to achieve the desired final look.

Quality Control

Quality control is an essential aspect of the custom 3D printed jewelry design process. Each piece goes through rigorous inspection to ensure that it meets the highest standard of quality. This includes checking for any imperfections or defects, verifying dimensions and measurements, and assessing overall durability. Quality control ensures that the final jewelry piece meets or exceeds your expectations and is ready for wear or gifting.

Design Considerations for Custom 3D Printed Jewelry

Choosing the Right Software

When designing custom 3D printed jewelry, it is crucial to choose the right software for creating the digital models. There are various CAD software options available, each offering different features and capabilities. It is essential to select software that is user-friendly, compatible with the 3D printer being used, and provides the necessary tools for intricate jewelry design.

Understanding Design Limitations

While 3D printing technology offers great design freedom, it is essential to understand its limitations. Certain design elements may be challenging to reproduce, such as extremely delicate and thin structures or intricate patterns that require support structures during the printing process. It is crucial to work closely with a jewelry designer who is familiar with the capabilities and limitations of 3D printing technology to ensure that your design can be successfully realized.

Material Selection and Compatibility

Material selection plays a significant role in the design of custom 3D printed jewelry. Different materials offer varying aesthetics, durability, and weight, which affect the overall look and feel of the jewelry piece. Additionally, it is essential to consider the compatibility of the material with the 3D printer being used, as some printers may have specific material requirements. Working with a skilled jewelry designer can help you navigate the material selection process and choose the best option for your desired design.

Balancing Aesthetics with Comfort and Durability

When designing custom 3D printed jewelry, it is essential to strike a balance between aesthetics, comfort, and durability. While you may be drawn to intricate and visually striking designs, it is crucial to consider the practicality of the piece. Jewelry should be comfortable to wear and durable enough to withstand everyday use. A skilled jewelry designer can guide you in creating a design that not only looks beautiful but also meets your functional requirements.

Popular Custom 3D Printed Jewelry Design Techniques

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is one of the most common 3D printing techniques used in jewelry design. This technique involves melting a thermoplastic filament and depositing it layer by layer to create the final jewelry piece. FDM is known for its simplicity, cost-effectiveness, and compatibility with a wide range of materials, making it a popular choice for custom 3D printed jewelry.

Stereolithography (SLA)

Stereolithography (SLA) is an additive manufacturing technology that uses a vat of liquid photopolymer resin and a UV laser to selectively cure the resin and build the jewelry piece layer by layer. SLA offers high precision and detail, making it ideal for producing intricate and delicate jewelry designs. It provides a smooth surface finish and allows for the use of resin materials with a wide range of properties.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a 3D printing technique that uses a high-power laser to selectively fuse powdered materials, such as nylon or metals, to create the jewelry piece. SLS allows for the creation of complex geometries and offers a wide range of material options. This technique is particularly suitable for producing jewelry with intricate, organic shapes or designs that require high strength and durability.

Digital Light Processing (DLP)

Digital Light Processing (DLP) is a 3D printing technology that uses a digital micromirror device (DMD) to project UV light onto a vat of liquid photopolymer resin, curing it layer by layer to create the jewelry piece. DLP offers high resolution and speed, making it suitable for producing finely detailed pieces with smooth surfaces. It is a versatile technique that allows for the use of a wide range of resin materials.

Custom 3D Printed Jewelry for Special Occasions

Wedding and Engagement Rings

Custom 3D printed jewelry is an excellent choice for wedding and engagement rings. These special occasions call for unique and personalized designs that symbolize the commitment and love between individuals. With 3D printing technology, you can create intricate and customized ring designs that are tailored to your preferences. Whether you want to incorporate meaningful symbols, initials, or birthstones, custom 3D printed jewelry allows you to create one-of-a-kind rings that hold immense sentimental value.

Anniversary and Birthday Gifts

Custom 3D printed jewelry also makes for memorable anniversary and birthday gifts. The ability to personalize the design and include special elements, such as birthstones or engraved messages, makes the gift even more meaningful. From elegant necklaces to statement earrings, custom 3D printed jewelry offers a wide range of options to suit different tastes and styles.

Graduation or Promotional Memorabilia

For graduations or promotional events, custom 3D printed jewelry can be used to create memorable memorabilia. Whether it’s a unique pendant or a custom-made bracelet, these jewelry pieces serve as a lasting reminder of the accomplishment or event. Custom 3D printed jewelry allows for the inclusion of logos, names, or dates, making each piece a personal keepsake.

Personalized Charms and Pendants

Custom 3D printed jewelry also offers the opportunity to create personalized charms and pendants. These small accessories can be added to a necklace or bracelet, allowing individuals to showcase their personal preferences or commemorate significant moments, such as the birth of a child or a memorable vacation. Customized charms and pendants make for thoughtful gifts that hold sentimental value and can be cherished for years to come.

Considerations for Material Selection in 3D Printed Jewelry

Types of Materials Used in 3D Printing

In the world of 3D printing, there is a wide variety of materials available for creating jewelry. Precious metals like gold, silver, and platinum are commonly used to achieve a luxurious and high-quality finish. Other metals, such as stainless steel and titanium, are also popular due to their strength and durability. Additionally, there is a range of resin materials available that offer various colors, translucency, and flexibility.

Properties and Attributes of Different Materials

Each material used in 3D printing comes with its own set of properties and attributes that influence the final appearance and functionality of the jewelry. Metals like gold and silver offer a timeless and elegant finish, while plastics and resins allow for greater flexibility in terms of color, texture, and translucency. It is essential to consider factors such as durability, weight, hypoallergenic properties, and the desired aesthetic when selecting the material for your custom 3D printed jewelry.

Color and Texture Options

With 3D printing, there is a vast array of color and texture options available for custom jewelry design. When using precious metals, the traditional colors of gold, silver, and rose gold are readily achievable. However, advancements in technology also allow for the application of different finishes, textures, and even patterns on metal surfaces, giving you greater design freedom. With resin materials, you can choose from a wide range of vibrant colors and even achieve translucent or gradient effects.

Cost and Availability

Material selection also needs to consider the cost and availability of the chosen materials. Precious metals tend to be more expensive compared to plastics and resins, which may be more cost-effective options for certain designs. Availability may also vary depending on the material and the specific 3D printer being used. It is important to work closely with a knowledgeable jewelry designer who can guide you in selecting the material that best fits your budget and design needs.

Custom 3D Printed Jewelry for Fashion and Trends

Unique and Avant-garde Designs

Custom 3D printed jewelry offers endless possibilities for creating unique and avant-garde designs that push the boundaries of fashion and trends. The versatility of 3D printing technology allows designers to experiment with unconventional shapes, textures, and even materials that were previously difficult to achieve. This opens up new avenues for creativity and innovation in the world of jewelry design.

Incorporating Geometric and Organic Shapes

Custom 3D printed jewelry provides the opportunity to explore geometric and organic shapes in a way that traditional manufacturing methods cannot replicate. The precise and intricate detailing that 3D printing offers allows for the creation of complex geometric patterns and structures. At the same time, it allows for the replication of organic forms found in nature, such as flowers, leaves, or animal-inspired designs. The ability to seamlessly combine these shapes results in truly unique and captivating jewelry pieces.

Integrating Minimalism and Abstract Patterns

Minimalism and abstract patterns continue to be popular trends in fashion and jewelry design. Custom 3D printed jewelry lends itself well to these design aesthetics, allowing for clean lines, sleek forms, and abstract patterns. Whether you prefer a simple pendant necklace or a pair of minimalistic earrings, 3D printing technology can bring these understated designs to life with precision and elegance.

Exploring Translucent and Gradient Effects

Translucent and gradient effects have gained popularity in recent years, adding depth and visual interest to jewelry designs. With 3D printing, it is possible to achieve these effects by using resin materials that offer varying levels of transparency or by incorporating multiple colors in a single piece. This opens up exciting opportunities for creating jewelry that captures the play of light and color, resulting in visually stunning and unique pieces.

Sustainable and Eco-friendly Aspects of Custom 3D Printed Jewelry

Reduced Material Waste

One of the notable benefits of custom 3D printed jewelry is the reduced material waste compared to traditional manufacturing methods. Traditional jewelry-making often involves cutting, shaping, and refining raw materials, resulting in a significant amount of wasted material. In contrast, 3D printing technology uses only the exact amount of material needed for each piece, minimizing waste and maximizing resource efficiency.

Localized Production

Custom 3D printed jewelry supports localized production, reducing the need for long-distance transportation of finished products. This not only cuts down on carbon emissions associated with shipping but also stimulates local economies by supporting local artisans and manufacturers. By embracing custom 3D printed jewelry, individuals can contribute to sustainable practices by choosing locally produced pieces.

Lower Carbon Footprint

3D printing technology itself has a lower carbon footprint compared to traditional manufacturing methods. Traditional manufacturing often requires a significant amount of energy for machinery, transportation, and other processes. In contrast, 3D printing consumes less energy during production, resulting in reduced carbon emissions. By opting for custom 3D printed jewelry, you can make a conscientious choice to reduce your carbon footprint and support sustainable manufacturing practices.

Ethical Material Sourcing

Custom 3D printed jewelry allows for the use of ethically sourced materials, such as recycled metals or environmentally friendly resins. With increased awareness of the social, environmental, and ethical impact of jewelry production, consumers are seeking jewelry that aligns with their values. 3D printing technology enables designers and manufacturers to utilize materials that have been responsibly sourced, ensuring that your custom jewelry is not only beautiful but also ethical.

Challenges and Limitations of Custom 3D Printed Jewelry

Initial Investment in Equipment

Setting up a custom 3D printed jewelry workshop requires an initial investment in equipment, including a 3D printer, CAD software, and other necessary tools. While the cost of 3D printers has decreased over the years, it is still a significant investment that may be challenging for individuals or smaller-scale jewelry businesses. However, as the technology continues to advance, the costs are expected to decrease further, making it more accessible to a wider audience.

Skill Requirements and Learning Curve

Creating custom 3D printed jewelry requires specific skills and knowledge of both jewelry design and 3D printing technology. Jewelry designers must familiarize themselves with CAD software and understand the capabilities and limitations of 3D printers. There is a learning curve involved in mastering these skills, and it may take time to become proficient in the design and production process. However, with dedication and practice, jewelry designers can acquire the necessary skills to excel in the field.

Limited Size and Structural Capabilities

While 3D printing technology continues to advance, there are still limitations in terms of size and structural capabilities. For larger, more complex jewelry designs, traditional manufacturing methods may still be more suitable. Additionally, certain design elements, such as extremely delicate structures or hollow forms, may require additional support structures during the printing process. These limitations need to be considered when designing custom 3D printed jewelry to ensure that the final piece can be successfully printed and meets the desired aesthetic and functional requirements.

Post-processing Challenges

After the 3D printing process is complete, custom 3D printed jewelry often requires post-processing to achieve the desired finish. This can include polishing, sanding, or applying surface treatments or coatings. While these post-processing techniques are necessary to refine and enhance the final appearance of the jewelry, they can be time-consuming and require additional skill and expertise. It is important to work with a jewelry designer who understands the post-processing requirements and can ensure that the final piece meets your expectations.

Future of Custom 3D Printed Jewelry Design

Advancements in Printing Technology

The future of custom 3D printed jewelry design is promising, with ongoing advancements in printing technology. As 3D printers become more sophisticated and capable of producing larger and more complex jewelry pieces, the design possibilities will expand. It is expected that future advancements will further improve the resolution, precision, and speed of 3D printers, allowing for the creation of even more intricate and detailed designs.

Integration of Smart Features

With the rise of wearable technology, the integration of smart features into custom 3D printed jewelry is a possibility for the future. This could include the incorporation of sensors, LEDs, or even miniature electronics into jewelry pieces. Custom 3D printed jewelry holds the potential to become not only aesthetically pleasing but also functional and interactive, allowing individuals to showcase their style while enjoying the benefits of smart technology.

Mass Customization and On-demand Production

Mass customization and on-demand production are expected to become more prevalent in the custom 3D printed jewelry industry. With 3D printing technology, it is possible to create custom designs at scale, allowing individuals to personalize their jewelry to a greater extent while still benefiting from cost-effective production methods. On-demand production eliminates the need for large inventories and wasteful overproduction, making custom 3D printed jewelry a more sustainable and efficient option.

Collaboration with Traditional Jewelers

The future of custom 3D printed jewelry may involve collaboration between traditional jewelers and 3D printing experts. While 3D printing offers unique design possibilities, traditional jewelry-making methods continue to hold value in terms of craftsmanship and expertise. By combining the best of both worlds, designers and manufacturers can create custom 3D printed jewelry that showcases the beauty and precision of 3D printing technology while incorporating the artistry and tradition of traditional jewelry-making.

In conclusion, custom 3D printed jewelry offers numerous benefits, including unique and personalized designs, precise detailing, cost-effective production, and quick turnaround time. The process of custom 3D printed jewelry design involves conceptualization and designing, 3D modeling and CAD software, material selection, printing and finishing, and quality control. When considering custom 3D printed jewelry, it is essential to choose the right software, understand design limitations, select materials, and create a balance between aesthetics, comfort, and durability. Various 3D printing techniques, including FDM, SLA, SLS, and DLP, can be used to bring custom jewelry designs to life. Custom 3D printed jewelry is suitable for special occasions such as weddings, anniversaries, graduations, and personalized gifts. Material selection in 3D printed jewelry should consider the types of materials used, their properties and attributes, color and texture options, as well as cost and availability. Custom 3D printed jewelry can cater to fashion trends, sustainability, and eco-friendliness, while also facing challenges and limitations such as initial investment, skill requirements, and post-processing challenges. The future of custom 3D printed jewelry is exciting, with advancements in printing technology, integration of smart features, mass customization and on-demand production, and collaboration with traditional jewelers paving the way for further innovation in the industry. With its endless possibilities and the ability to create truly unique and personalized pieces, custom 3D printed jewelry is transforming the world of jewelry design.